- What are graphite gaskets used for?

- Common Graphite Gasket Materials

- Features And Benefits Of Using Graphite Gasket

- Applications For Graphite Gaskets

- Graphite Gasket FAQs

- Contact us to get the right graphite gasket

There are many different types of gaskets. Each one has specific features which make them the best choice for certain applications and uses. Gaskets can be made from various materials depending on the requirements and indeed the manufacturing process. Graphite gaskets are one of the most popular choices that are used on the market today. In this guide, we’ll discuss the materials used for graphite gaskets, the features and some of the common facts that may be of interest to you.

What are graphite gaskets used for?

Graphite gaskets are mainly used for high-pressure and high-temperature sealing solutions, and can act as a mechanical seal. Graphite gaskets are used to fill the space between two surfaces or parts that are connected. Gaps will always occur regardless of how close you put two surfaces together. The problem with these gaps is that they will often cause issues with leakages. This happens due to the different parts moving or being under certain levels of compression.

Graphite gaskets provide the right answer. The space is filled and it helps to ensure the two different pieces remain aligned. This also guarantees that the greatest performance levels are achieved.

Related article: 4 Types of Automotive Gaskets Intro & What is a gasket?

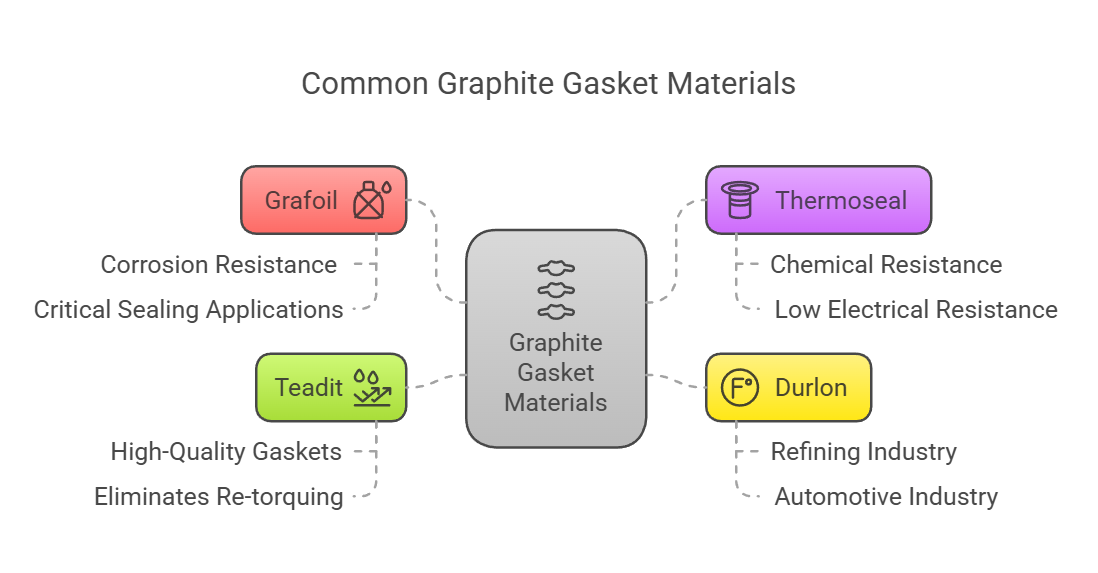

Common Graphite Gasket Materials

There are three commonly used graphite materials which are chosen to ensure that the gaskets remain flexible and adapt to different changes. These include:

- Pure graphite sheet

- Graphite sheet that is reinforced with a tang core

- Laminated graphite sheet with stainless steel insert

Gaskets are typically produced using a sheet and role material. This material has a density of 70 lb/ft 3 (1.1 g/cc). Graphite sheets for engine gaskets are also available with thicknesses ranging from 1.6mm to 2.0mm.

Graphite gaskets can be manufactured from material graphite. This contains a total level of carbon content that is between 90 - 99%. The percentage of carbon positively correlates with the amount of flexibility provided by graphite gaskets.

Graphite gaskets can also be reinforced with a variety of different materials. This includes aluminum foil, nickel alloy, wire mesh and polyester film. The material ensures that the gasket has additional levels of strength which guarantee the best possible performance.

Graphite gaskets may also be made from branding materials that are popular in the industry. These materials are available in a range of different thicknesses and styles depending on applications and requirements.

Grafoil

This material is made from 100% graphite. As such, it does not contain any inorganic filler materials or resins. One of the key benefits of this option is that it is highly resistant to levels of corrosion from various different substances including acids, salt solutions and heat transfer fluids. It is designed specifically for critical sealing applications. This includes internal combustion engines.

Thermoseal

Thermoseal material for graphite gaskets meets industrial grade sheeting and boasts a high level of chemical resistance. As it is both compactable and compressive, it ensures low gas permeability and low resistance from electricity.

Durlon

Durlon gaskets remain unaffected by heat at a variety of different temperatures. It is mainly used in the refining, automotive and petrochemical industries. This material can also be used for applications that require cryogenic temperatures.

Teadit

Teadit graphite gaskets can have a range of benefits. For instance, they will provide pressure temperature sealability benefits that are beyond other non-asbestos sheet products with similar levels of reinforcement. These high quality gaskets also have low creep relaxation. As such, re-torquing is not usually required.

Related article: Concise Gasket Material Types For Gasoline And Selection

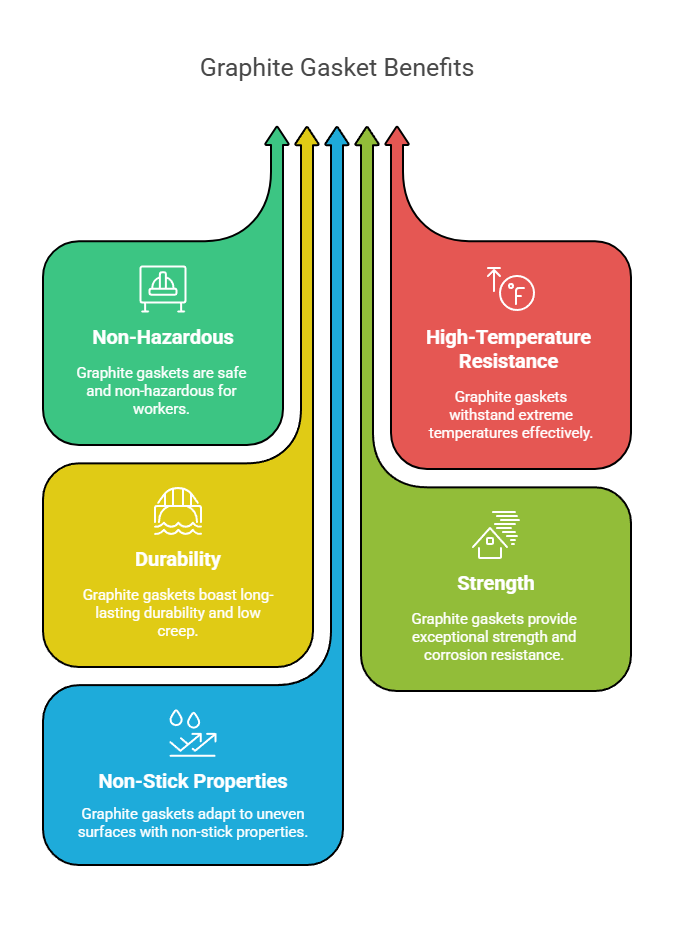

Features And Benefits Of Using Graphite Gasket

There are numerous different benefits of graphite gaskets which is why they are chosen for so many industrial applications.

Non-Hazardous

Graphite is also non hazardous and as such is compliant with both the Restriction of Hazardous Substances Directive as well as the Registration, Evaluation, Authorization and Restriction of Chemicals.

This also means that the gaskets are safe for employees who work with them on a daily basis. There’s no danger when the gaskets need to be installed or replaced and no special requirements needed.

Resistant To High Temperatures

A key feature and also a benefit of graphite gaskets is that they are resistant to high temperatures. This means that they can be used in countless industries where extreme temperatures are required. We’ll discuss some of the key examples a little further down. The heat resistance can also be further enhanced through the use of the right metal core. This is true for some of the materials listed above.

Graphite gaskets are also resistant to a wide range of different chemicals. This is one of the reasons why they are considered to be such a versatile solution.

Durability

Graphite gaskets have a low level of creep relaxation. Essentially, this means that they don’t age overtime. As such, it will be a while before they need to be replaced. They can offer the right long term solution for a range of industrial applications. The gaskets also have low ash content with consistent textile strength and density.

Strength

These gaskets have incredible strength. That makes them a perfect option for environments considered to be heavy duty which demand long-term reliability. Graphite also remains resistant to corrosion regardless of the heat or pressure that is being faced at the time. This is not the case for other types of gaskets that are often considered.

Non Stick Material

Graphite is a carbon material. This means it’s slippery because the layers of carbon atoms can move over one another. So, it’s perfect for closing up a gasketed joint because it can move around to fill uneven gaps. It can even manage issues with imperfections on the surface and flange deformations.

So, as well as providing a strong seal, these gaskets are going to be easy to remove and replace, saving any business time and money.

Applications For Graphite Gaskets

Some of the applications for graphite gaskets include:

- Dry sheet lubricants

- Heat dissipation barrier

- Chemical shields

- Cooling towers

- Chemicalplants

- Equipment which utilizes hot oil

- Heat exchangers

Since graphite gaskets have such impressive features they can be used in countless industries to provide unique benefits. Some of the key industries include paper, cryogenic and electrochemical plants. Gaskets like this can also be used to maximize the level of vibration damping as well as for thermal applications and steam services.

We hope this helps you understand the importance of graphite gaskets and why they are used so much in different industries. These gaskets can provide countless benefits which ensure that they are constantly chosen for key applications. As a top supplier of gaskets, we can deliver the materials that you need. Alternatively, you can get in touch to gain more information about the different gaskets available and advice on the right choice for your requirements.

Graphite Gasket FAQs

Are Graphite Gaskets Reusable?

Since graphite gaskets are highly versatile and change after the first compression, they are fantastic for providing the best quality sale possible. However, these are not reusable because of the changes they go through during the first level of compression. Instead, they need to be replaced.

What Is The Temperature Range Of Graphite Gaskets?

Graphite gaskets may hold temperatures of up to 3000 degrees celsius when used in atmospheres that are non-oxidising. Certain graphite gaskets can also withstand low temperatures of -20 degrees celsius. This is why it’s important to ensure that you choose the right type of graphite gasket made from the best material for your application.

How Long Do Graphite Gaskets Last?

Similar to other types of gaskets, graphite gaskets are not impacted by storage time. When stored correctly, they can last for more than ten years with no signs of degradation. Graphite gaskets can also be in constant use without any issues or signs of warping.

Are graphite gaskets oil resistant?

As this article mentioned here, one of the key benefits of graphite gaskets is that they are highly resistant to corrosion from various substances, including oils, acids, salt solutions, and heat transfer fluids.

Is graphite head gasket better?

When considering resistance to high temperatures (450°C), the heat resistance of graphite gaskets is better than that of metal gaskets. Graphite gaskets can be used in countless industries where extreme temperatures are required.

Contact us to get the right graphite gasket

The MEGA Gasket manufacturer has extensive experience in engine gaskets and providing tailored advice and solutions for clients operating across a variety of industries. We can provide customized advice and recommendations based on your requirements. Contact us by filling in this online enquiry form.

|

Author: MEGA Gasket established since 1979, granted ISO 9002 in 1999 and updated to ISO 9001:2015 in 2017, and the main production is for automobile and all kind of engine gaskets. MEGA have profuse experience and good reputation in Taiwan. Learn more about MEGA Gasket manufacturer and supplier. |